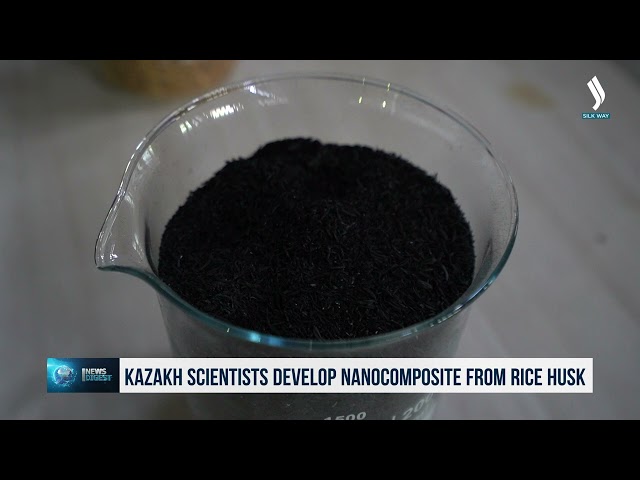

Kazakh scientists have developed a

revolutionary material – a silicon carbon nanocomposite derived from rice

husks. This unique product will be manufactured at a specialized facility with

an annual capacity of 1,500 tonnes. According to the project authors, rice husk

is a renewable raw material. The product obtained from its processing can be

utilized as a filler for rubber products, friction materials, and as a raw

material for silicon and ferroalloys. The nanocomposite can be applied in

agriculture and for manufacturing anodes for lithium-ion batteries. It is worth

noting that the National Center for Integrated Processing of Mineral Raw Materials

is implementing the project with the support of the Science Fund. State support

for the project amounted to 300 million tenge, with 60 million tenge invested

by the manufacturer.

«Kazakhstan produces a substantial volume

of rice, resulting in a significant amount of rice husk waste, which can

account for up to 20 percent of the total mass. Rice husk contains a large

amount of silicon dioxide. While the project primarily aims at import

substitution, there is also potential for export,» noted Serik Mazhikenov, the

Director of the Department of Technology Commercialization at the Science Fund.